Support Team

Feedback:

support@nextpcb.comChoosing a reliable quick-turn PCB manufacturer is critical to the success of your project—whether it's for prototype development, small-batch production, or urgent delivery. When facing tight deadlines, project delay risks, or the need to seize market opportunities, fast PCB prototyping and delivery become especially crucial.

NextPCB fully understand the challenges you face with urgent PCB requirements. Therefore, with 15 years of PCB industry experience, NextPCB is committed to providing you with excellent quick-turn PCB solutions. As a leading quick-turn PCB manufacturer, NextPCB has not only accumulated strong technical expertise but also established a rigorous quality management system and an efficient response mechanism.

Quick Turn PCB refers to the service of completing PCB manufacturing and delivery in a very short time period, typically from order to shipment in just 24 hours to 5 days (traditional PCB production usually takes 2 to 4 weeks).

Shortens Product Development Cycle: Quick Turn PCB allows you to rapidly validate designs during the early stages of product development, significantly reducing the time from concept to prototype and seizing market opportunities.

Reduces R&D Costs: Fast iteration and validation can promptly identify and correct design flaws, preventing significant losses that may arise from discovering issues only after mass pcb production, thereby effectively lowering overall R&D costs.

Seize Market Opportunities: In the face of unexpected orders or urgent projects, Quick Turn PCB helps you quickly respond to market changes, ensuring products are launched on time and capturing fleeting business opportunities.

Flexibility and Adaptability: Especially suitable for small-batch, diverse, and urgent order needs, offering a high degree of production flexibility.

Risk Control: By utilizing fast pcb prototyping, you can identify and resolve potential design or functional issues early stage, effectively mitigating risks in later stages.

Among many options, a professional Quick Turn PCB manufacturer offers you not just speed, but also quality and peace of mind. When you choose a specialized Quick Turn PCB manufacturer like NextPCB, you gain:

By choosing NextPCB, you can be confident that your project will be completed on time and with outstanding quality. They continuously invest in technological innovation to meet your most demanding design requirements. Whether it's complex multilayer boards or high-precision HDI boards, NextPCB delivers reliable support through strong manufacturing capabilities and a professional technical team—helping you meet market challenges with confidence and accelerate time to market.

Achieving rapid delivery for quick-turn PCBs is not just about fast production—it's about integrating every stage from order placement to final shipment into an efficient, responsive system. NextPCB is your trusted partner, continuously investing in and optimizing the following areas to provide you with unmatched quality service. Explore our <<Step-by-Step Guide to the PCB Manufacturing Process>> and discover what makes fast, reliable delivery possible behind the scenes. You can enjoy NextPCB's service:

Once your design files are uploaded, they are immediately processed by an automated system for Design for Manufacturability (DFM) analysis. If no issues are detected, the intelligent review system automatically approves the design. After payment, the order enters the production scheduling system. Compared to traditional manual review, NextPCB saves 1–2 days for order reviews.

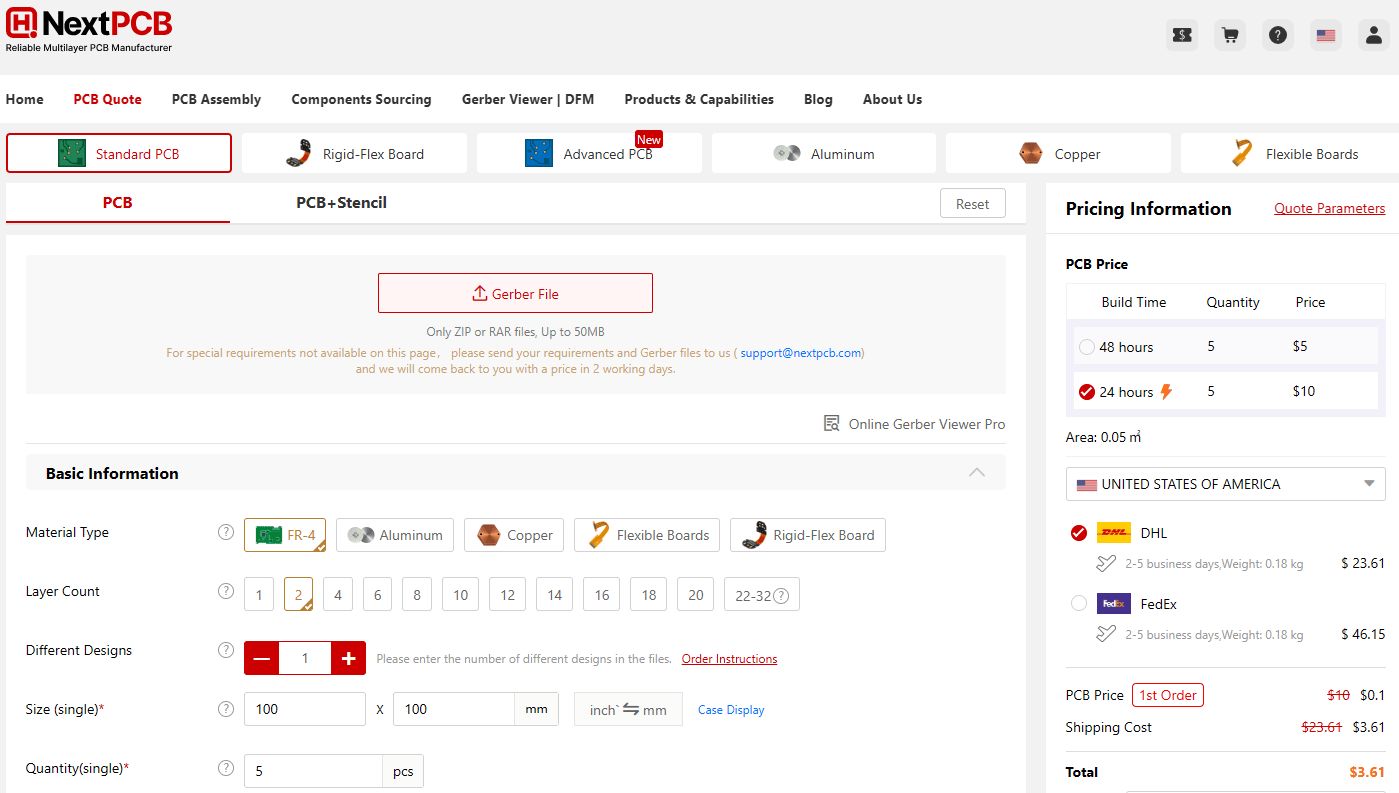

NextPCB website supports fast uploads of design files such as Gerber and KiCad, and provides accurate, transparent pricing within minutes. Whether for PCB or PCBA prototyping, real-time online pricing is available. This eliminates the usual 1–2 days spent waiting for manual quotations in traditional processes. Quote Online Now

NextPCB maintain long-term partnerships with high-quality suppliers to ensure sufficient stock of commonly used PCB substrates and key auxiliary materials—or the ability to quickly source them. Strong and stable supply chain management significantly reduces the risk of delays due to material shortages.

NextPCB utilizes high-precision, automated production equipment such as high-speed drilling machines, automated exposure units, and AOI inspection systems. These reduce manual operation time and increase overall production efficiency. Key process parameters are also optimized to shorten durations in steps like exposure, etching, and electroplating.

NextPCB's team of engineers brings deep expertise in PCB design and manufacturing. They offer free technical consultations including DFM and DFA analysis, and can quickly resolve any production issues that arise.

NextPCB works with multiple renowned logistics providers to ensure your custom PCBs are delivered quickly and securely anywhere in the world. Through these critical measures, they truly realize "Quick Turn" from order to delivery—making NextPCB your reliable expert in rapid PCB manufacturing.

| PCB Layer | PCB Size | PCB Quantity | PCB Quick turn Time |

| single layer PCB | Size < 100mm | 5-10 pieces | 24 hours |

| double layer PCB | Size < 100mm | 5-10 pieces | 24 hours |

| 4 layer PCB | Size < 100mm | 5-10 pieces | 48 hours |

| 6 layer PCB | Size < 100mm | 5-10 pieces | 72 hours |

| 8 layer PCB | Size < 100mm | 5-10 pieces | 72 hours |

If you want to know the factors that affect the cost of custom PCB or custom PCBA, you can refer to <Custom PCB and PCBA Cost Analysis>.

The rapid response capability of quick turn PCBs makes them indispensable across a wide range of industries:

Selecting a suitable Quick Turn PCB manufacturer is crucial for the success of your project. Here are some key points to consider when making your decision:

To quickly realize PCB prototyping, NextPCB makes this process exceptionally simple. With just the following six steps, you can easily get it done:

First, you need to prepare your Gerber files. Simply put, Gerber files are the "blueprints" of PCB design. They contain detailed information for each layer of the circuit board (such as copper layers, solder mask layers, legend layers, etc.), serving as the basis for PCB manufacturers to proceed with production. Ensuring your Gerber files are accurate is the key first step to successful prototyping. You can lear more from <<Gerber Files for PCBs: Creating, Viewing, and Converting>>.

NextPCB offers a 24/7 online quoting system that allows for transparent pricing. You just need to upload your Gerber files and check the required parameters, and the system will immediately provide a quote, giving you clear insight into the costs.

After confirming the price, you can directly submit your order. NextPCB uses an intelligent review system, meaning over 90% of PCB orders can be reviewed in just a few seconds. This is significantly faster than manual review, which typically takes 1-2 business days, greatly saving your time.

Payment supports various secure methods including Credit Cards, PayPal, Aliexpress and Bank Transfers, ensuring payment security.

After payment, the order automatically enters the scheduling system, awaiting production. NextPCB allows for real-time tracking of the production progress.

After production is completed, NextPCB defaults to vacuum packaging, and special products will use special packaging.

Our quick turn PCB lead times are flexible, with expedited delivery available in as fast as 24 hours (exact time depends on design complexity and order quantity). Whether you need a single prototype for concept validation or small-batch production for initial market demand, we offer adaptable manufacturing solutions.

In general, due to expedited production and special scheduling, the unit cost of quick turn PCBs may be slightly higher than that of standard PCBs in large volumes. However, thanks to years of process optimization, our quick-turn prototyping costs have been normalized—and are now even more affordable than traditional prototyping.

Absolutely. Quality is always our top priority. Despite the shorter production cycle, we strictly follow all quality standards and inspection procedures, including AOI, X-ray, and flying probe testing. This ensures our quick turn PCBs meet or even exceed the quality of standard PCBs.

We support a wide range of materials including FR-4, high-frequency boards, high-Tg boards, and metal-based substrates. Advanced manufacturing processes are also available, such as multilayer boards, HDI, blind and buried vias, impedance control, gold plating, ENIG (Electroless Nickel Immersion Gold), and more—to meet your diverse needs.

Simply upload your Gerber files or KiCad files via our online platform to place an order. For special requirements, our sales team is available to assist you throughout the ordering process.

In addition to PCB fabrication, we also provide PCB assembly services and component sourcing—saving you time and effort with a true one-stop PCB solution.

Order Quick Turn PCB OnlineView NextPCB CatalogView NextPCB Certificates

NextPCB Exclusive Offers to Support Your Projects and Growth in 2025

Limited Offer for New Customers: PCB Prototype from $0.1/10pcs, Free Shipping

Save $200 on Professional Turnkey PCB Assembly from HQ NextPCB

FREE Functional Testing for your Prototype PCBA with HQ NextPCB (blog)

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|